2022 CoPROPEL

CoPropel puts forth a holistic approach towards the realisation of marine propellers made of advanced composite materials. Compared to their traditional counterparts, marine composite propellers offer efficiency gains in propulsion efficiency, noise reduction and weight savings. The CoPropel project will see an interdisciplinary team of experts drawn both from research and industry, from theoretica lconsiderations and numerical modelling to precision manufacturing - assembly and experimental verification testing. The CoPropel action brings together 9 organisations from 5 countries: 4 Research Institutes – TWI, University of Ioannina, Brunel University London and The Bulgarian Ship Hydrodynamics Centre; 4 Industrial partners – Loiretech, MECA, Danaos and Glafcos Marine with one certification body Bureau Veritas Marine & Offshore. Together, we will develop and bring to market a marine composite propeller with an embedded structural health monitoring system. The proposed activities will mature our Technology Readiness Level to 5-6 and drastically de-risk the integration of the investigated solutions on future products, effectively resulting in reducing the direct operating costs for the operators while minimising the environmental impact. Existing work by the partners has shown an approximate 12% reduction in energy consumption and subsequent fuel consumption, with the potential savings exceeding 15% at full-scale marine vessel propellers, which will be investigated and confirmed during our real-time sea trials as part of the CoPropel project.

CoPropel puts forth a holistic approach towards the realisation of marine propellers made of advanced composite materials. Compared to their traditional counterparts, marine composite propellers offer efficiency gains in propulsion efficiency, noise reduction and weight savings. The CoPropel project will see an interdisciplinary team of experts drawn both from research and industry, from theoretica lconsiderations and numerical modelling to precision manufacturing - assembly and experimental verification testing. The CoPropel action brings together 9 organisations from 5 countries: 4 Research Institutes – TWI, University of Ioannina, Brunel University London and The Bulgarian Ship Hydrodynamics Centre; 4 Industrial partners – Loiretech, MECA, Danaos and Glafcos Marine with one certification body Bureau Veritas Marine & Offshore. Together, we will develop and bring to market a marine composite propeller with an embedded structural health monitoring system. The proposed activities will mature our Technology Readiness Level to 5-6 and drastically de-risk the integration of the investigated solutions on future products, effectively resulting in reducing the direct operating costs for the operators while minimising the environmental impact. Existing work by the partners has shown an approximate 12% reduction in energy consumption and subsequent fuel consumption, with the potential savings exceeding 15% at full-scale marine vessel propellers, which will be investigated and confirmed during our real-time sea trials as part of the CoPropel project.

CoPropel is funded by the European Climate, Infrastructure and Environment Executive Agency (CINEA), Project: 101056911

2020 Innovation-el

Innovation-el is a large-scale distributed research infrastructure of cutting-edge facilities that covers all fronts from materials synthesis, characterization and functionalization to micro-nanofabrication, device/system design, development and testing. The network is complemented by multiscale computer simulations and theory, and is supported by more than 200 skilled scientists of long-standing expertise and interdisciplinary experience.

CSML participates in the project with Raman spectroscopy equipment.

INNOVATION-EL is implemented under the “Reinforcement of the Research and Innovation Infrastructure” Action (MIS 5002772), funded by the Operational Programme “Competitiveness, Entrepreneurship and Innovation” (NSRF 2014-2020) and co-financed by Greece and the European Union (European Regional Development Fund)

http://innovation-el.staging2.scify.org/

https://harvest.project.

HARVEST is a 36 month project that will cover the whole value chain of Fiber Reinforced Plastics (FRPs) so as to provide novel FRPs capable of harvesting and storing thermoelectric energy. In addition, HARVEST will develop a purposefully made electronic circuit module so as to power SHM inherent functionalities and provide information on the structural health of the components.

To this end, HARVEST is composed of an interdisciplinary consortium of academics, key technology providers, industrial/SME partners and standardization experts to ensure the applicability of the developed materials in future aerospace applications.

HARVEST project concept:

Development of multifunctional TEG-enabled structural composite materials for the Aeronautics sector.

HARVEST project will employ breakthrough technologies combining bio-inspired hierarchical ThermoElectric Energy Generating (TEG) carbon fiber (CF) reinforcements with novel thermoset matrix systems (3R Repair-Recycle-Reprocess technology). The “hierarchical” reinforcement will be comprised from a micron-scale CF coated with nano-scaled particles. The aim is to develop multifunctional TEG-enabled structural composite materials for the Aeronautics sector.

https://cordis.europa.eu/project/rcn/216003/factsheet/en

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 769140.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 769140.

2018 - ThermoformAble, repairable and bondable smart ePOXY based composites for aero structures

Composite & Smart Materials Laboratory (CSML) is delighted to announce that it will be participating in the AIRPOXY project from September 2018. AIRPOXY is a 42-month collaborative project funded by the European Commission in the HORIZON 2020 framework with a total budget of €6.5m. The aim of this project is to reduce production & MRO (maintenance, repair and overhaul operations) costs of composite parts in aeronautics. This will be achieved by introducing a novel and new family of enhanced composites that preserve all the advantages of conventional thermosets, while showing Re-processability, Reparability and Recyclability (3R). AIRPOXY will develop new thermoset resins from TRL3 (Technology Readiness Level) to TRL5 through two representative demonstrators of aircraft panels.

Composite & Smart Materials Laboratory (CSML) is delighted to announce that it will be participating in the AIRPOXY project from September 2018. AIRPOXY is a 42-month collaborative project funded by the European Commission in the HORIZON 2020 framework with a total budget of €6.5m. The aim of this project is to reduce production & MRO (maintenance, repair and overhaul operations) costs of composite parts in aeronautics. This will be achieved by introducing a novel and new family of enhanced composites that preserve all the advantages of conventional thermosets, while showing Re-processability, Reparability and Recyclability (3R). AIRPOXY will develop new thermoset resins from TRL3 (Technology Readiness Level) to TRL5 through two representative demonstrators of aircraft panels.

CSML will implement structural health monitoring (SHM) technologies in order to detect in service damage and analyze the damage tolerance of the new composites. CSML will test various specimens geometries for different levels of damage (matrix cracking, delaminations, etc.) and then, develop and optimize the SHM technologies using a variety of Non-Destructive (NDE) techniques. In the demonstrator level, CSML will integrate the developed SHM technologies for validation and further optimization.

The AIRPOXY project is led by CIDETEC and it is formed by a multidisciplinary consortium of 11 partners from 6 countries; CIDETEC (Spain) as resin inventor, key technology providers IVW (Germany) (thermoforming & welding), Eurecat (Spain) (RTM), Coexpair (Belgium) (SQRTM), University of Ioannina/Composite & Smart Materials Lab (Greece) (Structural Health Monitoring); Altair (France) (process simulation software), aircraft components manufacturers (EIRE, Ireland); IDEC, Spain); SONACA, Belgium), standardization experts UNE (Spain) and an aeroconsultancy (ARTTIC, France).

https://cordis.europa.eu/project/rcn/216013/factsheet/en

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No769274.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No769274.

2013- 2016 HIPPOCRATES, Small or Medium Scale (Aeronautics FP7) «SELF-HEALING POLYMERS FOR CONCEPTS ON SELF-REPAIRED AERONAUTICAL COMPOSITES»

• HIPOCRATES is a Collaborative Project co-funded by the 7th Framework Programme of the European Community. Further information on European Community research programmes can be found on the Cordis web site.

• The aim of HIPOCRATES project is to serve as a platform for developing the required knowledge, technologies, procedures and strategies to deliver self-repairing composite aero-structures, while defining the roadmap to achieve the vision of self-repairing composite structures.

In order to achieve this aim, the objectives of HIPOCRATES research and development activities are set to give answers in certain directions:

• To provide experimental evidence to meet the State-of–the-Art shortcomings and broaden the understanding of the self-healing mechanisms.

• To develop strategies and respective procedures for enabling self-repairing of composite materials by critically analyzing the established techniques.

• To establish novel routes and technologies for utilizing the self-healing functionalities in aero-structures.

• To develop new protocols and testing methods in order to specifically quantify the healing magnitude.

https://cordis.europa.eu/project/rcn/111157/brief/en

2009- 2013 IAPETUS,Small or Medium Scale (Aeronautics FP7) «Innovative Repair of Aerospace Structures with Curing Optimization and Life Cycle Monitoring Abilities»

Bonded composite patches are ideal for aircraft structural repair as they offer enhanced specific properties, case-tailored performance and excellent corrosion resistance. Bonding further eliminates stress concentrations induced from mechanical fastening of metal sheets, seals the interface, and reduces the risk of fretting fatigue between the patch and the component.

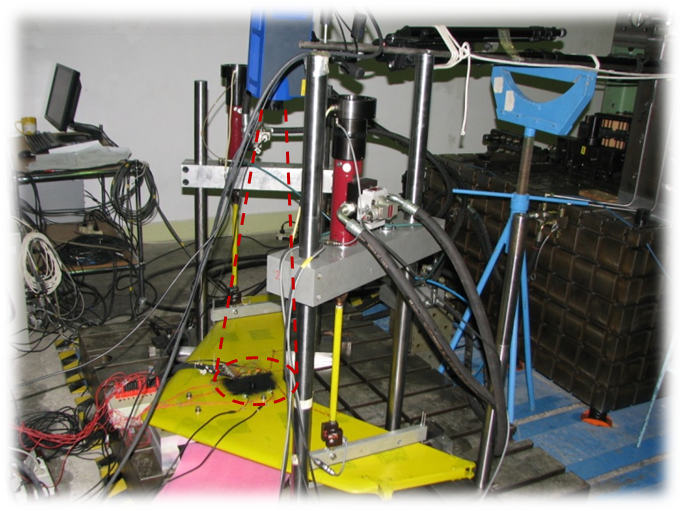

IAPETUS focuses on the use of improved composite repair systems offering (i) the introduction of new on-aircraft simplified curing technologies, (ii) enhanced fatigue and damage tolerance properties and (iii) integrated damage sensing. This will be performed via the incorporation of carbon nanotubes (CNTs) both in the composite matrix of the repair patch as well as in the adhesive. The use CNT modified repair concept will lead to improved performance in the blunting of stress concentrations in the parent surface and the inhibition of crack propagation, leading to enhanced fatigue resistance at the locus of the repair as well as for the patch itself.

At the same time, the patch repair acquires additional functionalities. The CNT doped Carbon Composites can be tailored to reduce the galvanic corrosion in repaired Aluminium structures. As the patch becomes electrically and thermally conductive thermal energy can be infused in the patch either by direct resistance heating (using the patch itself as heating element via the application of electrical voltage) or by induction heating, to instigate a uniform matrix polymerization since the patch system appears improved thermal conductivity too. The electrically conductive percolated network can be employed to assess the damage within the patch and its interface with the repaired structure, as conductivity changes mirror the damage in the doubler/substrate system by tracing micro damage through breaches in the CNT network; thus, the structural efficiency monitoring at any stage in the service life of the aerostructure can be assessed non-destructively.

IAPETUS is realised by 7 industrial partners (Fundación INASMET Spain, PZL-Swidnik Poland, Huntsman Advanced Materials GmbH Switzerland, Integrated Aerospace Sciences Corporation (INASCO) Greece, DAHER Aerospace France, GMI AERO France, Hellenic Aerospace Industry SA Greece) and 3 Universities (University of Ioannina Greece, University of Sheffield UK, University of Patras Greece).

https://cordis.europa.eu/project/rcn/91015/factsheet/en